SwitchMaster Switch Controller

Current Lionel TMCC products are aimed at new TMCC layouts that distribute the ‘intelligence’ around the layout in small bundles. Controllers such as the SC1 and SC2 can be placed near a cluster of switches. The disadvantage of this TMCC-only configuration is that there may be no manual controller/indicator at a central location.

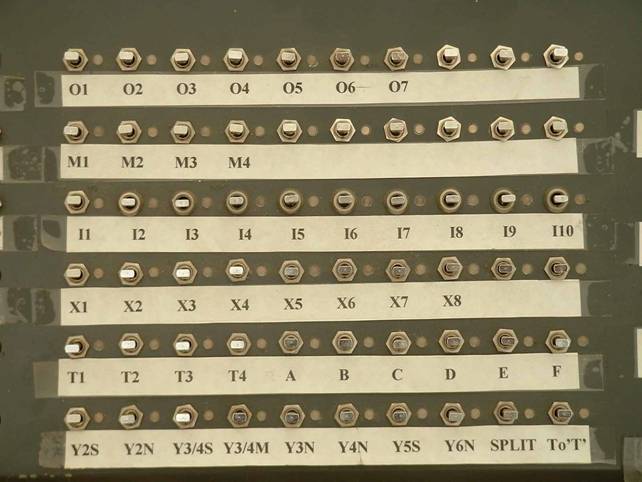

Classic layouts, on the other hand, usually have a central control location that includes all the switch controller/indicators for the entire layout. This configuration permits a quick scan of the indicators and immediate operation on any one switch. This cluster of controls begs for a single TMCC interface that can control many switches by simply tapping into the wiring to the controller/indicators at the central location.

The SwitchMaster is just what the doctor ordered. The modular system consists of a central controller and one to four relay boards that can each control 32 switches.

The central controller utilizes a PIC microcontroller with software developed by The Electric RR Company to decode the serial RS-232 commands from a Lionel Command Base and/or a computer through two separate 9-pin serial port inputs. The PIC can control up to 128 switches (4 relay boards). In addition, an auxiliary EEROM provides enough non-volatile memory to store up to 32 Routes of up to 128 switches each.

To provide maximum reliability, each switch control line is controlled by a heavy-duty relay with 13 amp contacts. The relay provides a contact closure to the common line of the relay circuit, which is usually ground for most switch types. The contact closure is a short pulse, providing sufficient energy to move the switch, but avoiding any excessive currents to a jammed switch or a switch sitting under a parked train. The current version is not intended to use with continuous-current devices such as Tortoise switch machines.

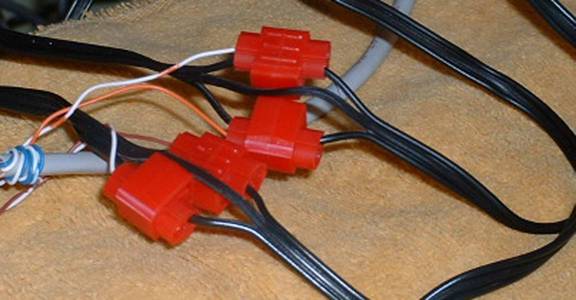

The interface to the relay board is via two 34-pin flat ribbon connectors per board. The wires from these connectors can be wired to existing terminal strips for the controllers if a convenient connection point exists. In the absence of terminal strips, the wires can be tapped onto the typical 3-wire cables of the controllers as shown below.

Up to four relay boards can be stacked, with interconnections between the boards provided by vertical risers between boards. One jumper on each board programs the relay board to the correct address block of 32 faders.

To avoid any grounding problems, power for the logic and relays is provided by an independent ‘wallwart’ power supply.

The following series of photos illustrates the installation of the first unit. The control panel already utilized flat ribbon cables to all the toggle switch/bicolor LED controller/indicators for 60 switches. These flat ribbon cables were tapped in groups of 32 switches plus 2 ground wires by simply crimping 34-pin headers onto the flat ribbon cables.

Jumpers of 34-wire flat ribbons connect the control panel to the relay boards.

The Command Base and computer share a common connector on the prototype, but this is expanded to 2 separate 9-pin connectors on the production version.